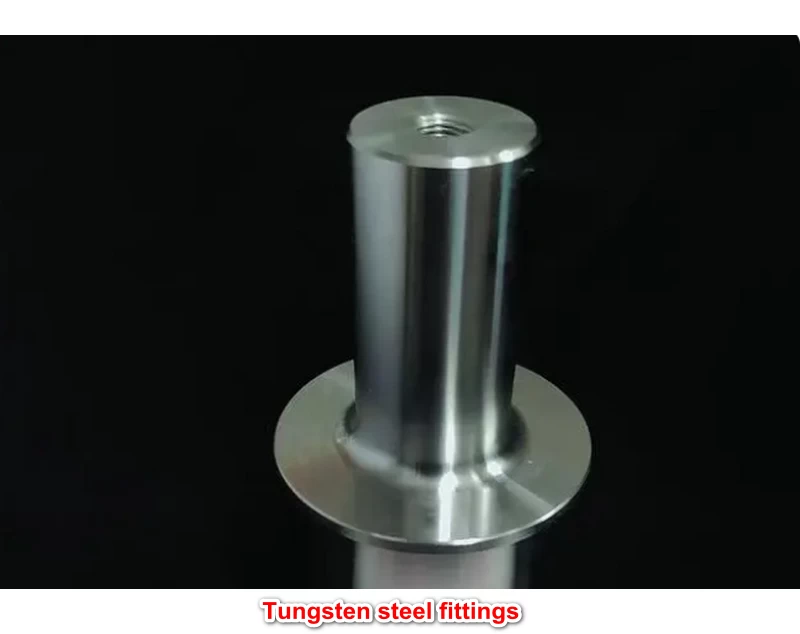

Introduction to tungsten steel fittings

Tungsten steel fittings have a wide range of applications, and its performance is good, but also can ensure long-term use effect. The hardness of tungsten steel itself is very high, strength, wear resistance and so on are also good. So what are the advantages of tungsten steel? How practical are the accessories?

Strong machining performance

In the process of drawing die processing, good processing effect can be guaranteed, and the processing size range of tungsten steel accessories is large, and some complex parts can also be processed. Especially some watch accessories, small parts can also be made of tungsten steel. Its high hardness, processing effect is good, can also ensure the stability of parts.

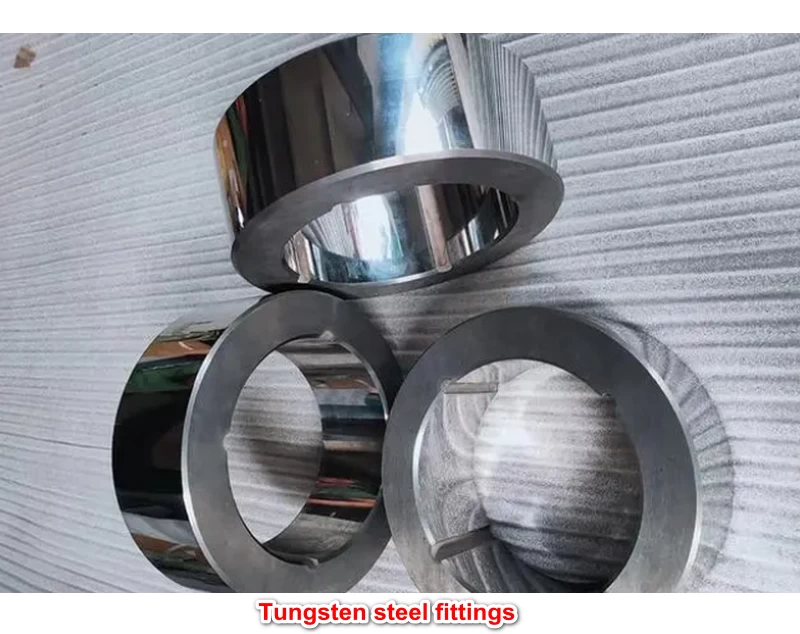

Long service life

Tungsten steel can ensure stable size, and high shape accuracy, precision parts can be used to make tungsten steel. And its surface quality is good, long-term stamping will not appear damage and other problems, the service life of the parts is also very long. Quality stability is guaranteed, the application effect is also guaranteed.

Low material consumption

When processing tungsten steel parts, there is generally no cutting debris, and the consumption of materials is also relatively small. And do not use other heating equipment processing, also can ensure the material saving, processing effect is also very good. The cost of stamping parts is relatively low, and the parts can guarantee long-term use, but also can ensure the long-term application of cost-effective.