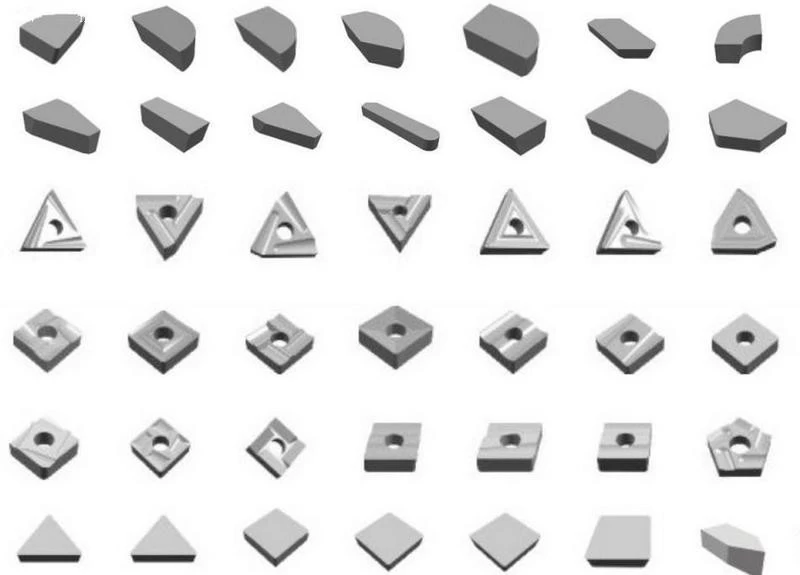

Tungsten Carbide Inserts

Tungsten carbide inserts (especially indexable tungsten carbide inserts) are the leading products of CNC machining inserts. In some countries, more than 90% of turning tools and more than 55% of milling tools are made of tungsten carbide. increasing. Since the 1980s, the tool industry has continuously expanded the production of various integral and indexable tungsten carbide tools or inserts, and its varieties have expanded to various cutting insert fields, among which indexable tungsten carbide inserts are made of simple turning tools. , Face milling cutters are expanded to various precision, complex and forming blade fields. tungsten carbide is also a common material for making general-purpose inserts such as drills and face mills. At the same time, the use of tungsten carbide for complex inserts such as reamers, end mills, medium and large modulus gear inserts for machining hard tooth surfaces, and broaches is also increasing. At present, the annual output value of tungsten carbide inserts and inserts has accounted for more than 30% of the total output value of cutting inserts

The leading edge of a tungsten carbide blade contains thousands of permanently bonded carbide particles and is one of the hardest materials known. Cutting materials that other blades can't handle, longer time, smooth surface, no embedded, mainly used for cutting tough and hard wear-resistant materials including glass fiber, composite materials, fiber cement, artificial marble, composite materials, circuit boards and other components . There is no loss in the cutting diameter of the steel plate. Fits popular portable benches and radial arm saws and can be mounted in either orientation.

Because tungsten carbide blades have good wear resistance, extremely sharp cutting tools are required in industry. For example, tungsten carbide blades are great for cutting and painting reflective materials. While prone to chipping and breakage, these defects can be avoided with proper engineering, and tungsten carbide inserts can withstand significant industrial stress. Some factories have found that while tungsten carbide blades are more expensive, their durability and ability to withstand pressure are worth the extra cost.

tungsten carbide blades last longer. Because of the heat and wear resistance of tungsten carbide, the blade is a wear-resistant material for cutting most building materials and extremely hard metals.

tungsten carbide blades are used to improve the versatility and productivity of slicing plastics. In these applications, tungsten carbide inserts are the primary tool for making embedded steel. The blades are all consistent and save the work of frequent replacements through thousands of applications.

Precautions for using tungsten carbide blades:

1. Cemented carbide is a hard and brittle material, which is brittle and damaged under the action of excessive force or some specific local stress, and does not have a sharp edge.

2. Most of the cemented carbides are mainly composed of tungsten and cobalt, with high density. They should be handled with heavy objects during transportation and storage, and handled with care.

3. Cemented carbide and steel have different thermal expansion coefficients. In order to avoid stress concentration cracking, attention should be paid to the appropriate temperature during welding.

4. tungsten carbide blades should be stored in a dry environment away from corrosive atmosphere.

5. During the cutting process, the tungsten carbide blade will inevitably produce chips, chips, etc. Please prepare necessary labor protection supplies before processing.

6. If the coolant is used in the cutting process, please use the cutting fluid correctly for the sake of the service life of the machine tool and the tool.

7. For the tool that has cracks during processing, please stop using it.

8. The tungsten carbide blade is dulled due to long-term use, and its strength is reduced. Please do not let non-professionals grind it.

9. Please keep the polished alloy knives and fragments of alloy knives in a safe place to avoid harming others.

tungsten carbide blade is one of our best products. It is very durable and can run for a long time in high speed cutting. Therefore, it can improve operational efficiency and reduce production costs.